Just finished my first in life "Instructable" at the D.I.Y. host site instructables. It is short sketch about Iambic Paddle which has been made using a spare parts from the dead MFM HDD drive. I got a lot of fun posting to that site, and I think that it should be good idea to post more detailed article here. Frankly, this homebrew project is not a Pure Glowing Bug, but I'm not so puristic today.

Just finished my first in life "Instructable" at the D.I.Y. host site instructables. It is short sketch about Iambic Paddle which has been made using a spare parts from the dead MFM HDD drive. I got a lot of fun posting to that site, and I think that it should be good idea to post more detailed article here. Frankly, this homebrew project is not a Pure Glowing Bug, but I'm not so puristic today.Well, let me explain - why I decided to use HDD heads as a levers in this Iambic Paddle Project. For many years I've collected computer spare parts for no reason, just because I have a big, nearly endless Junk Box and it was impossible to me to throw such high-tech toys in the trash. But one morning I found that my Junk Box is full and The Time of Trash Bags has come. It was a hard work, but under the tons of debris I found the treasure - my first homemade Z80 Sinclair Spectrum and five old 5 inch MFM hard drives from my second computer.

As you remember, these drives was a big rounded shaped boxes, ideal as a chassis for any homemade electronic projects, tube glowbugs as well as solid state stuff. Another interesting things - powerful electromotor and magnetic cylinders itself, thick shiny discs which are so usable as a dial or scale part, looked much better than a CD in this role. And last but not least - yes, precision bearings on the easy to mount axis in magnetic head's block. What a beautiful hardware! When I opened and totally disassembled these hard drives, I realized that I literally had a very new telegraph key, usual one lever, dual lever iambic paddle or even straight key - not so important, it is easy to make any kind of telegraph manipulator using these nice spare parts. Watch this video demonstrating a working Iambic Paddle and take a look at step by step constructing process here:

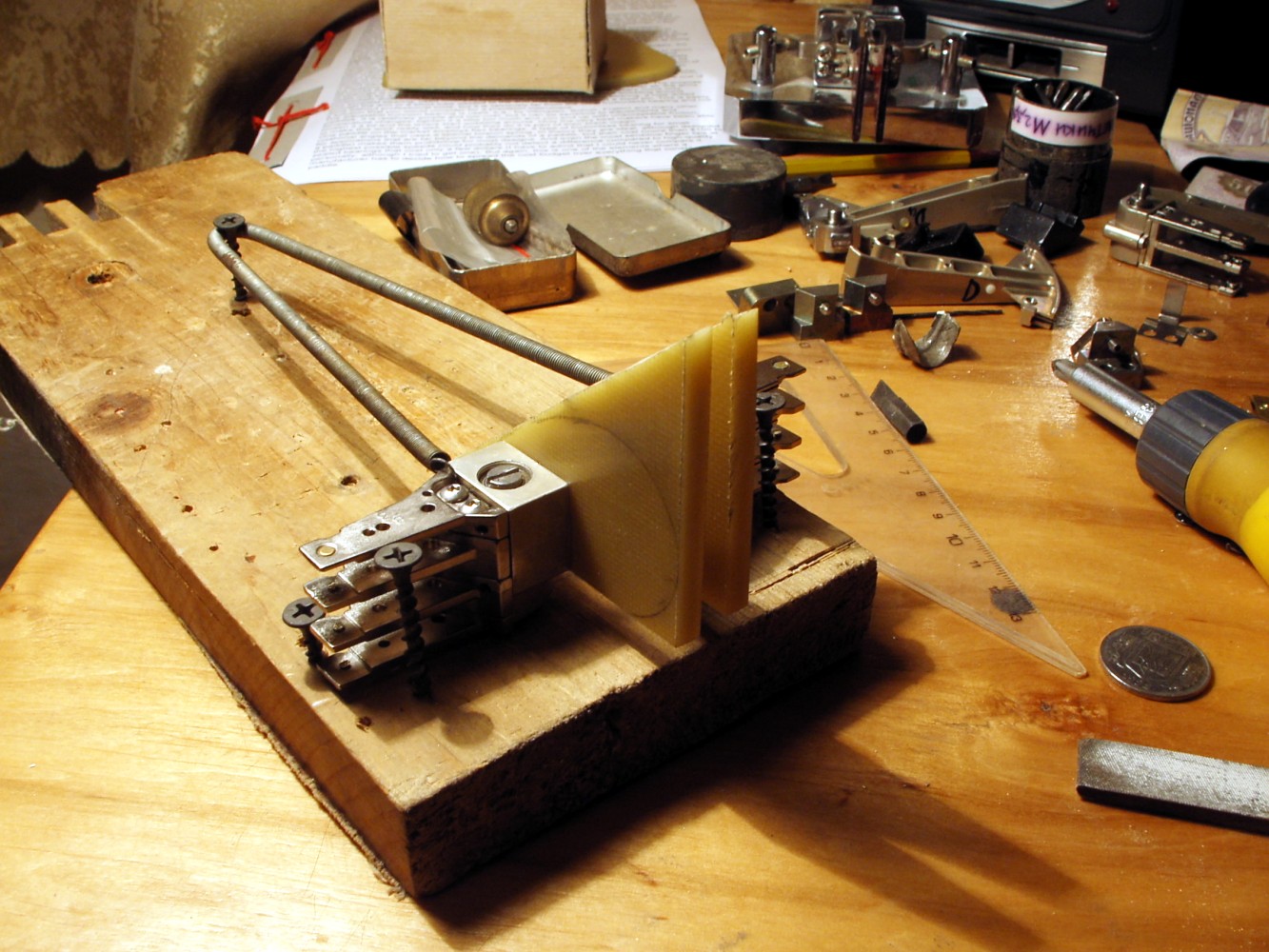

step 1: Extracting Heads from Dead Drives

step 2: Cut off fag end

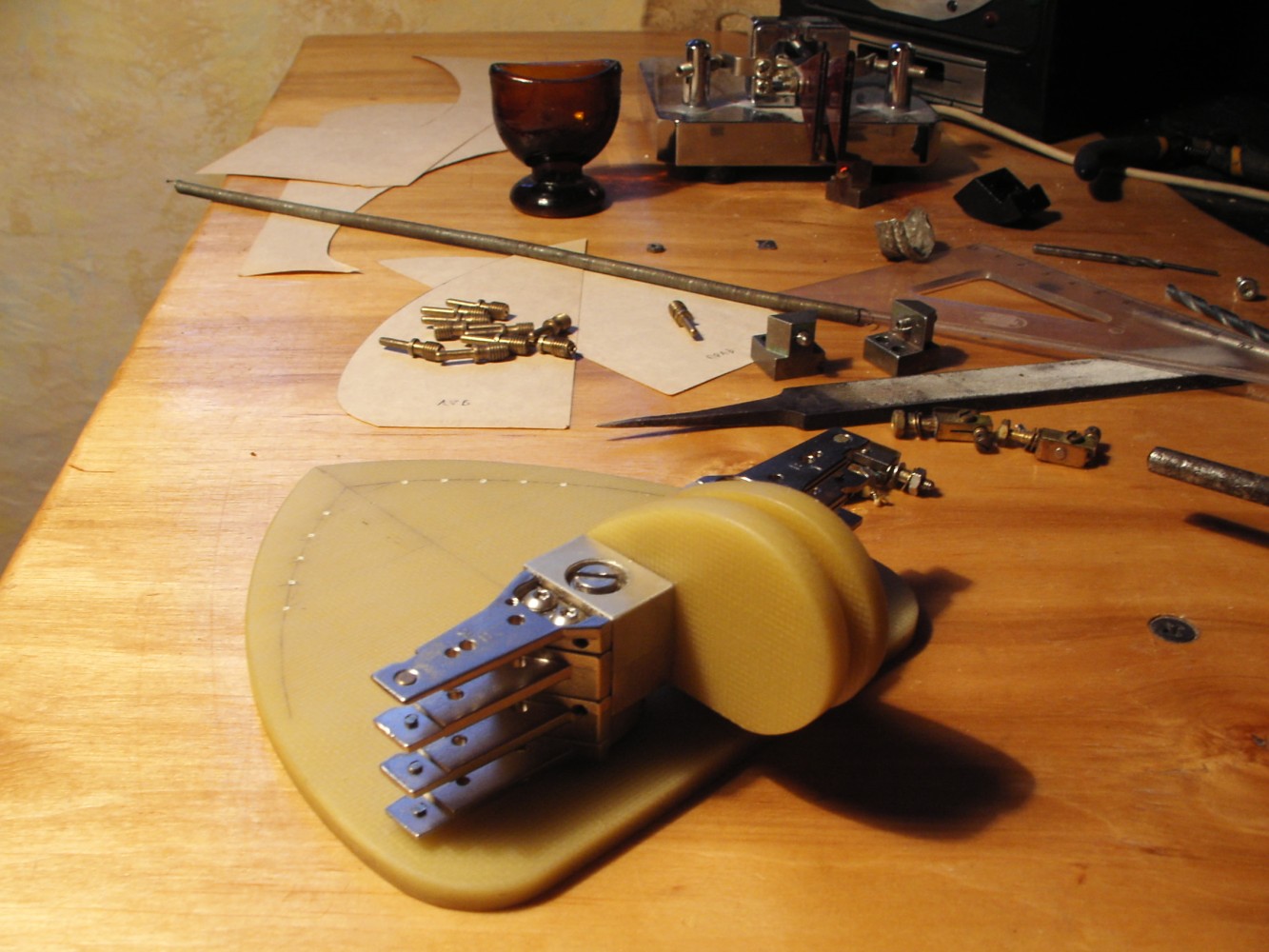

step 3: Breadboarding and making the plastic base.

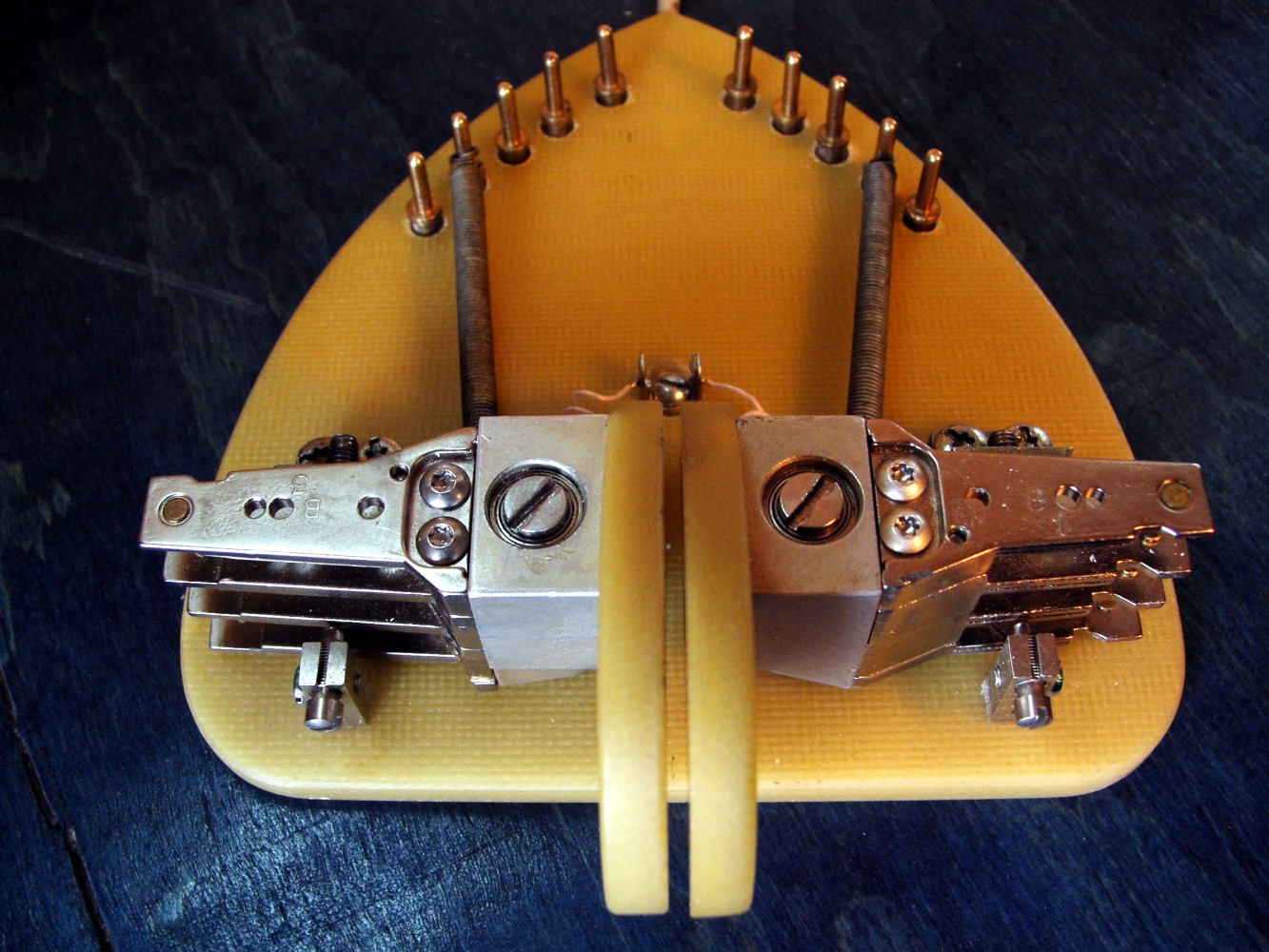

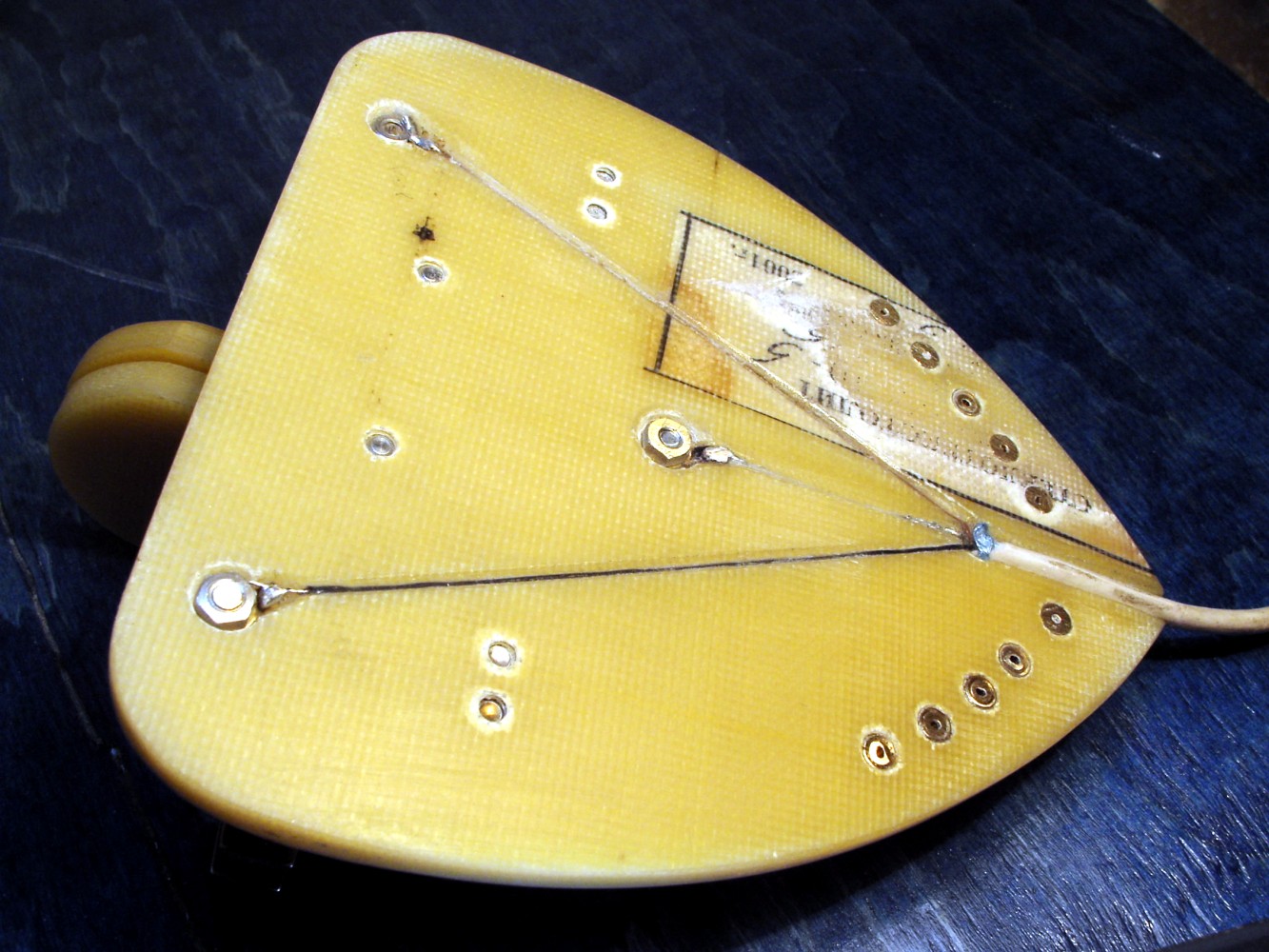

step 4: Assembly and assembled views

1 comment :

Great design ... and I can see you spent lots of time on it. Thanks for posting.

Post a Comment